Reuters: Bangkok According to a government official, Thailand is in talks to develop production facilities with China’s CATL and other battery manufacturers in Southeast Asia’s second-largest economy, which has aspirations to become a regional centre for EV production.

These debates take place as Thailand, a regional auto centre, works to displace China as a major participant in the global electric vehicle (EV) supply chain by providing tax breaks and subsidies to promote EV manufacture.

Narit Therdsteerasukdi, Secretary General of Thailand Board of Investment (BOI), stated, “We are talking to numerous firms, not just CATL but many companies in the battery industry.

“One of our objectives is this. that we hope to entice battery cell manufacturers to locate a manufacturing in Thailand.

Narit withheld information, thus it was unclear how far along the conversations were.

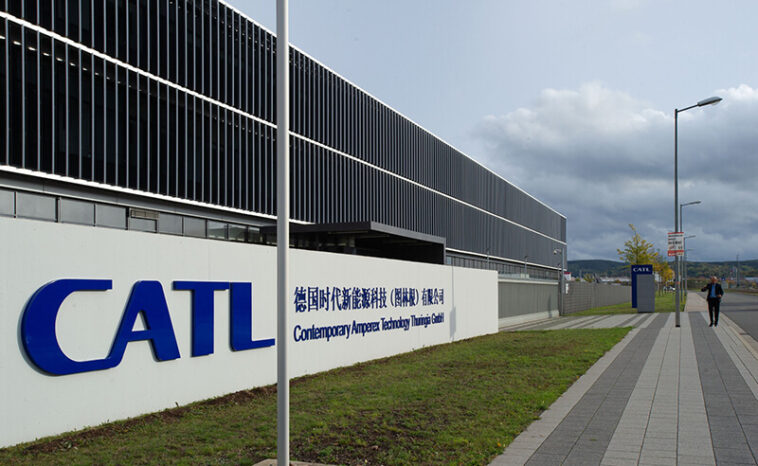

An inquiry for comment was not immediately answered by CATL, also known as Contemporary Amperex Technology Co Ltd.

According to its website, CATL, the largest battery provider in the world with a 37% market share, does not currently have any production facilities in Southeast Asia.

In order to “explore potential cooperation and development opportunities in battery-related business” in the area, the Ningde, Fujian-based company last year signed a strategic partnership with a subsidiary of Thai energy giant PTT Pcl.

The PTT subsidiary ARUN PLUS is a partner in a joint venture with Taiwan’s Foxconn that is constructing a factory with the intention of producing EVs in Thailand as early as 2024.Thailand is the tenth-largest auto manufacturing economy with production dominated by Japanese automakers including Toyota and Isuzu.

A government plan calls for Thailand to switch to EVs for about 30% of its 2.5 million annual vehicle output by 2030.

Thailand has attracted investments from EV firms in recent years, primarily Chinese firms like Great Wall Motors and BYD Co.

According to Narit, Thailand hopes to draw EV suppliers and assembly plants, as well as local production of batteries and other essential parts like chargers.

According to Narit, the government wants to focus support and incentives on building larger battery manufacturing plants.

According to him, Thailand is giving investments that will support facilities with a capacity of more than 8 gigawatt hours (GWh) first priority.

A 75 kilowatt-hour battery from that size plant could power more than 106,000 electric vehicles.

There are now 13 battery production hubs operated by CATL, 11 of which are located in China. It started ramping up output at its 14 GWh facility in Germany’s Erfurt region this year.

CATL, which has been quickly growing outside of China, has agreements with companies like Ford Motor, Honda Motor Co., and BMW. Tesla vehicles made in China as well as Volkswagen’s I.D. series are powered by its batteries.